WitMotion

[WTVB01-BT50] Bluetooth 50m Wireless Multi-connected Vibration Sensor

[WTVB01-BT50] Bluetooth 50m Wireless Multi-connected Vibration Sensor

Couldn't load pickup availability

If you have contact or agent in China,

pls directly reach us or forward their info.

Vibration meter Bluetooth 5.0

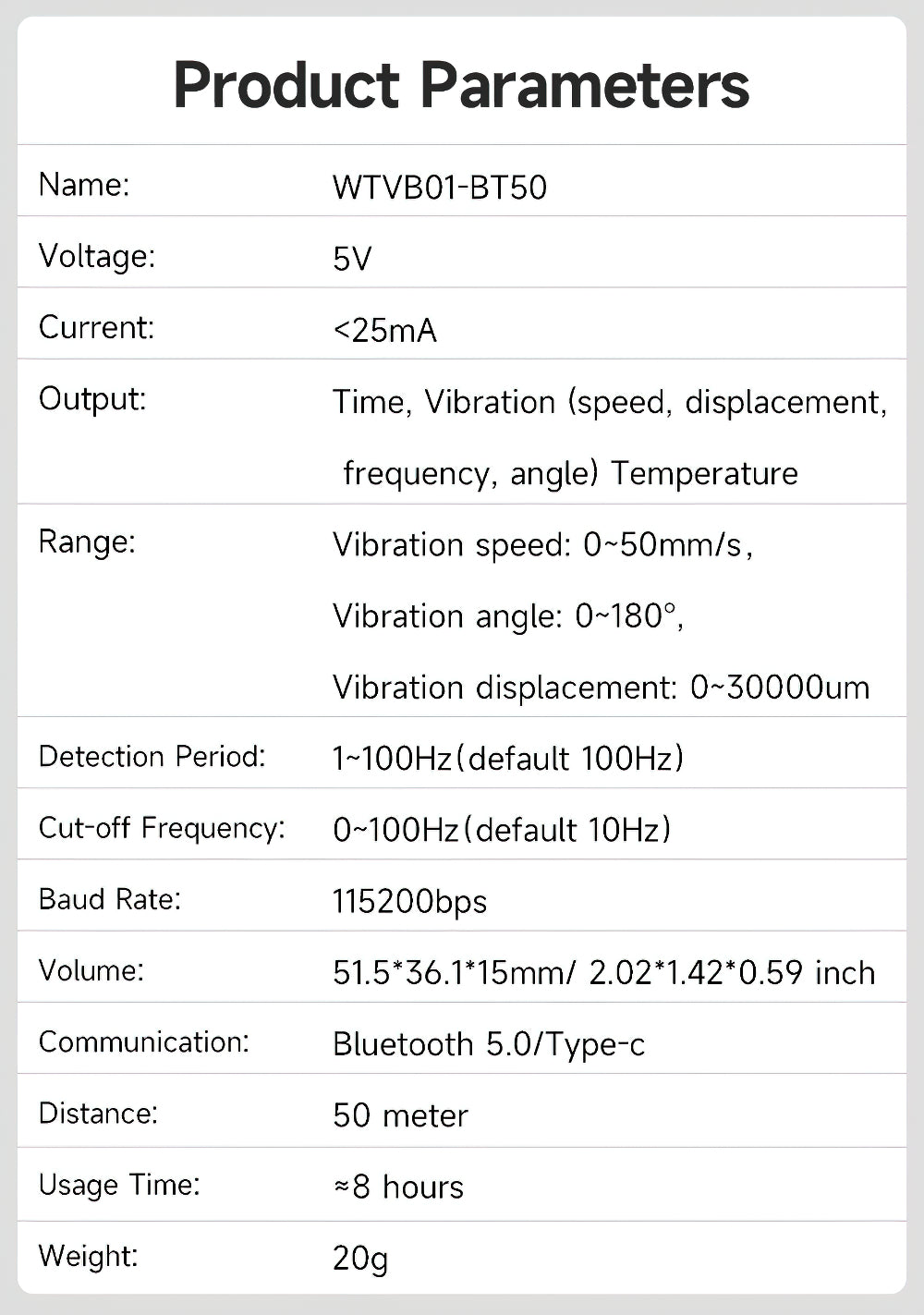

WTVB01-BT50

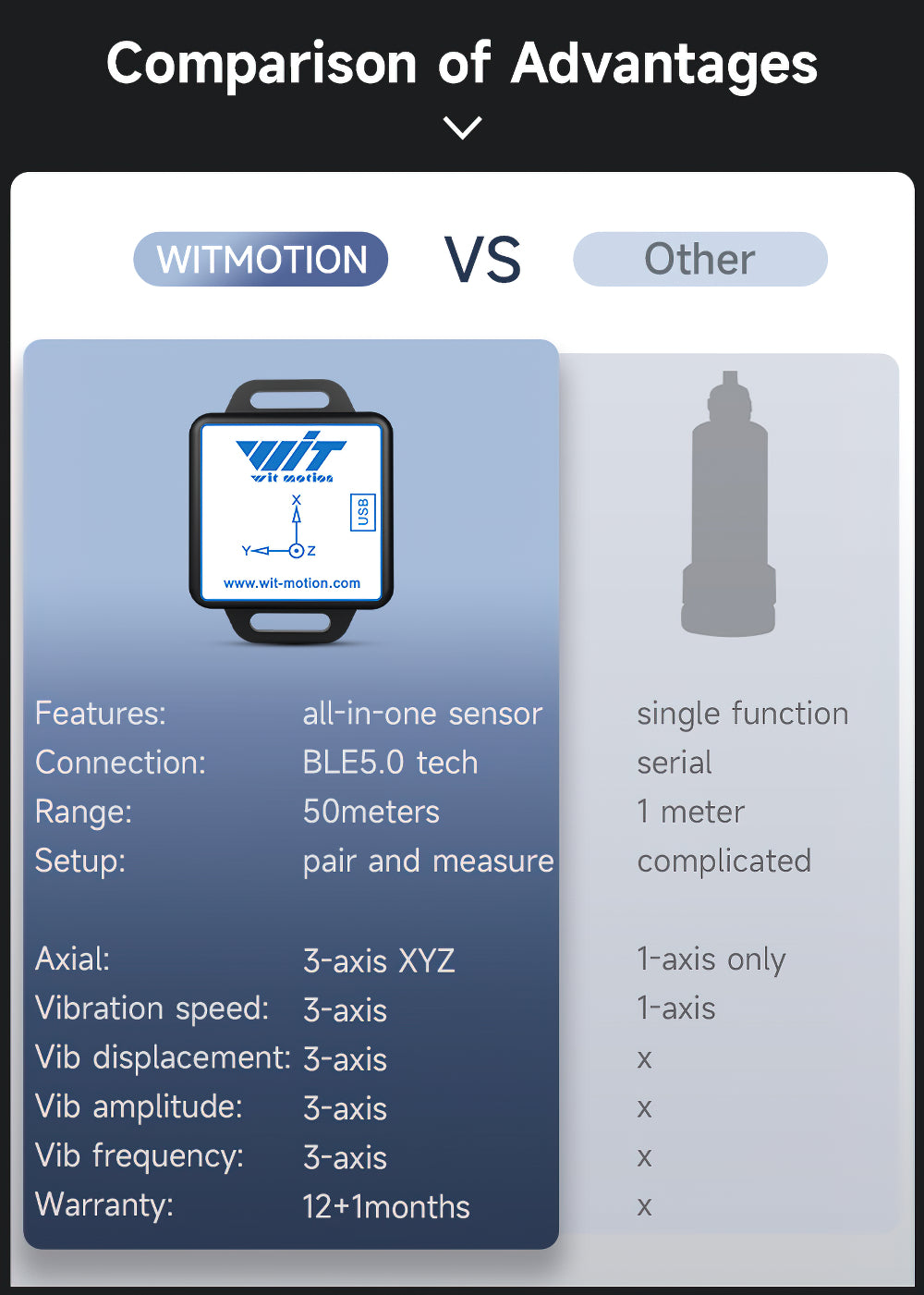

- 【High performance】 This vibration meter adopts advanced digital filtering technology, which can effectively reduce measurement noise and improve measurement accuracy.

- 【Adjustable frequency】The cut-off frequency ranges from 1 to 100 Hz, and the detection period ranges from 1 to 100 Hz.

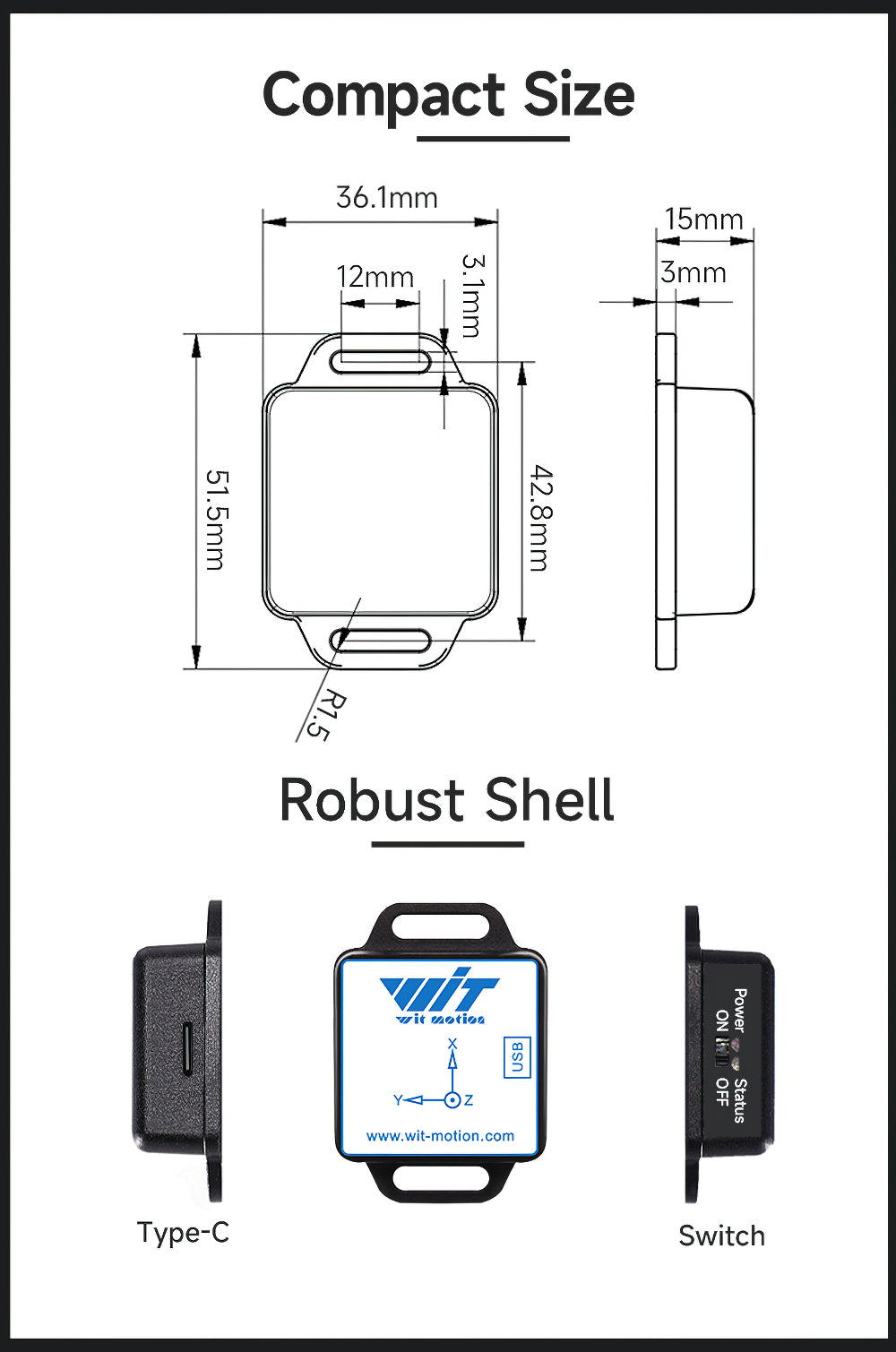

- 【Convenient Links】Supports Type-C interface, allowing users to choose the best connection method. Serial port rate is 115200bps.

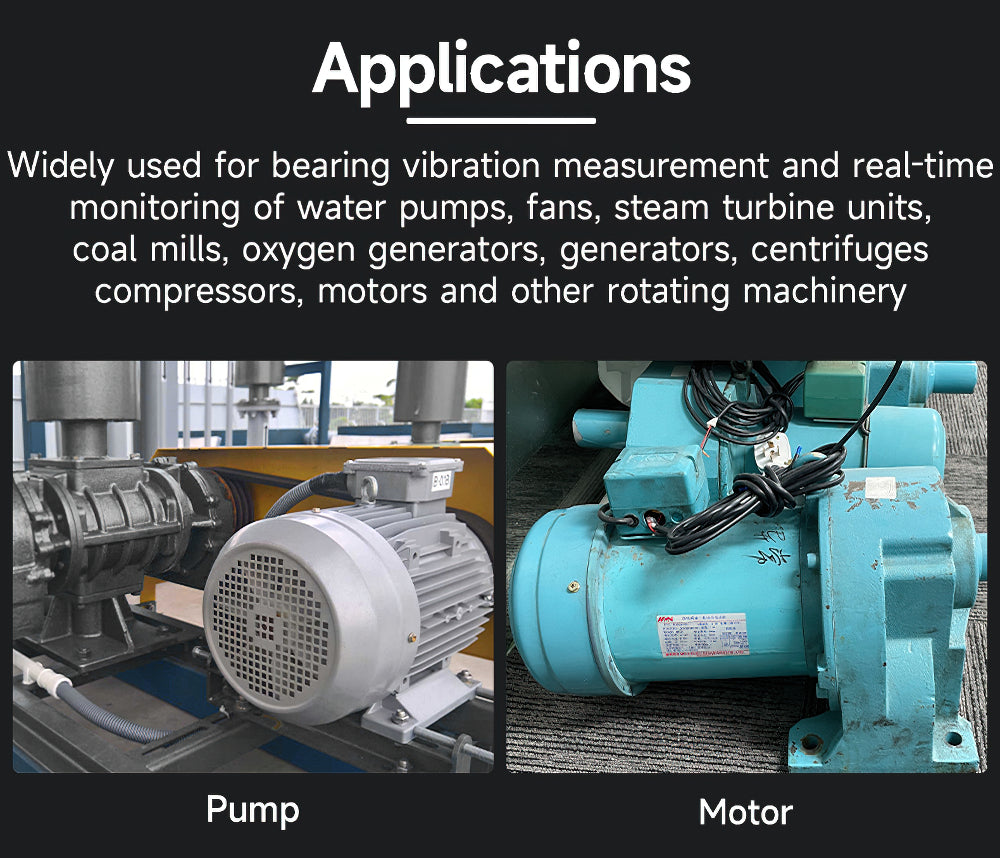

- 【Product Features】The vibration sensor WTVB01-BT50 can measure vibration and shock in all directions from motors and water pumps. If a machine failure is caused by bearing wear, bearing cracking, poor dynamic balance, or misalignment, the vibration sensor can detect the failure in advance and provide an early warning.

- 【Application Areas】The Bluetooth vibration sensor can be widely used in bearing vibration measurement and real-time monitoring of rotating machinery.

- 【Bluetooth5.0】The vibration sensor equip with Bluetooth 5.0, with a data transmission distance of more than 50m.

- 【You will get】WTVB01-BT50 vibration sensor*1, Type-c charge cable*1, Quick Start Guide*1.

- 【Support】Professional support team provides you with technical support.

Share

![[WT901SDCL-BT50] Bluetooth remote reading SD card Low-Power Accelerometer, 9-axis Gyro+Angle+Mag - WitMotion ShenZhen CO.,LTD](http://witmotion-sensor.com/cdn/shop/files/5.0.jpg?v=1742436210&width=1445)

Arrived in two and a half weeks, in the consolidated package, I did not check in the work, because I have not dealt with the software yet

Couldn't get the app to download. Extremely confusing. Returned

Sensor llego en excelentes condiciones, esperamos el inicio de pruebas para confirmar su efectividad en campo

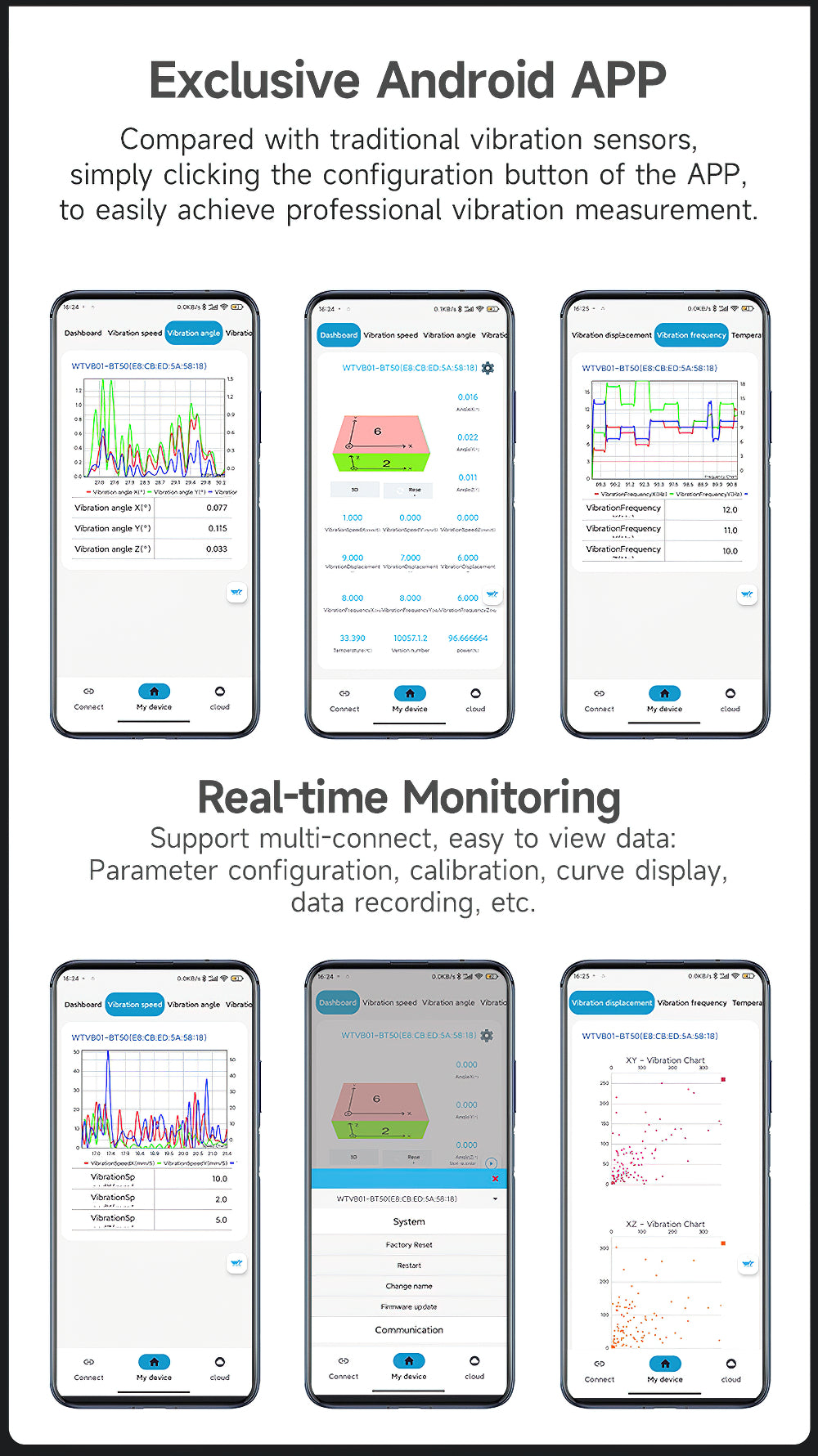

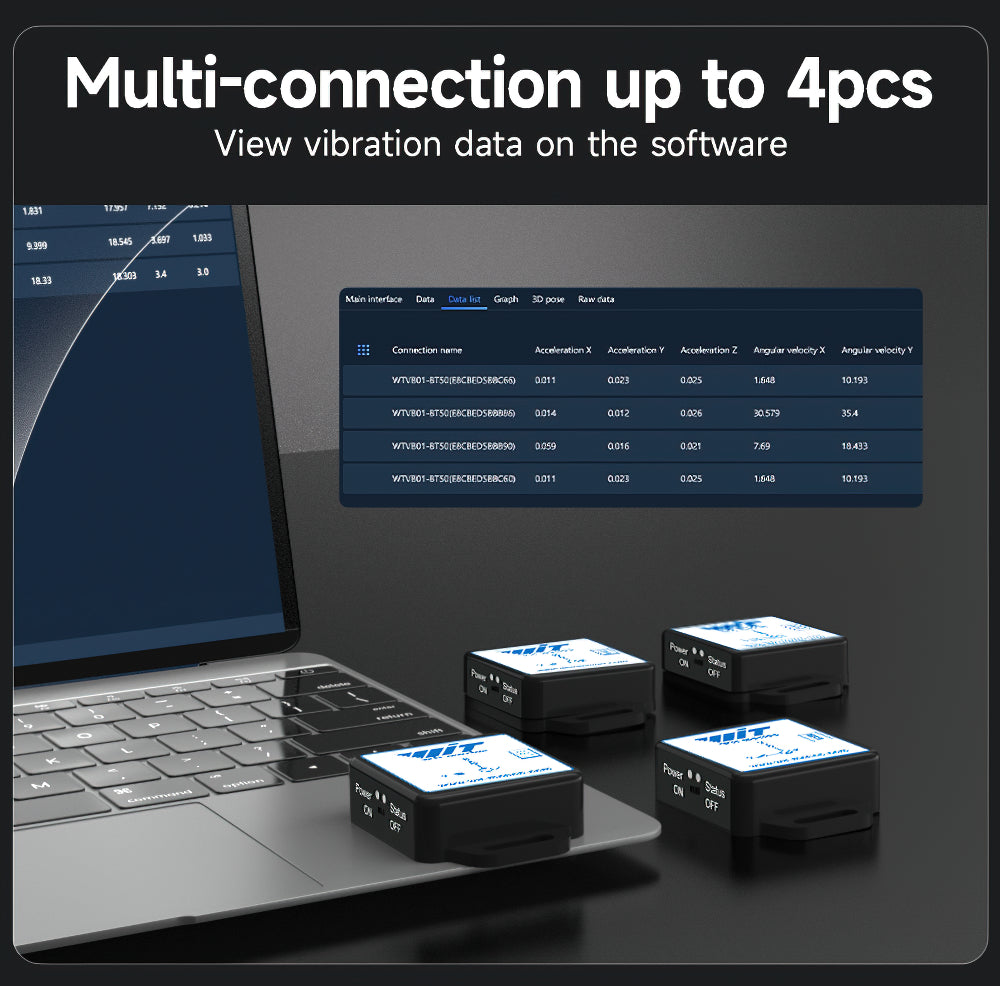

I like that this sensor is affordable and enables you to check equipment vibration to certain extent. Problem got complex when I tried to mount 6 sensors on a piece of machine to get the baseline information. Renaming the sensors was glitchy. I gave up after naming only two of them. I tried taking notes like e3:5e:84:36:57:5e was motor X, but that got cumbersome and made the data later hard to post process.

The software is glitchy too. Playing back the data means you have to re-watch the test in real time. Software needs a lot of work.

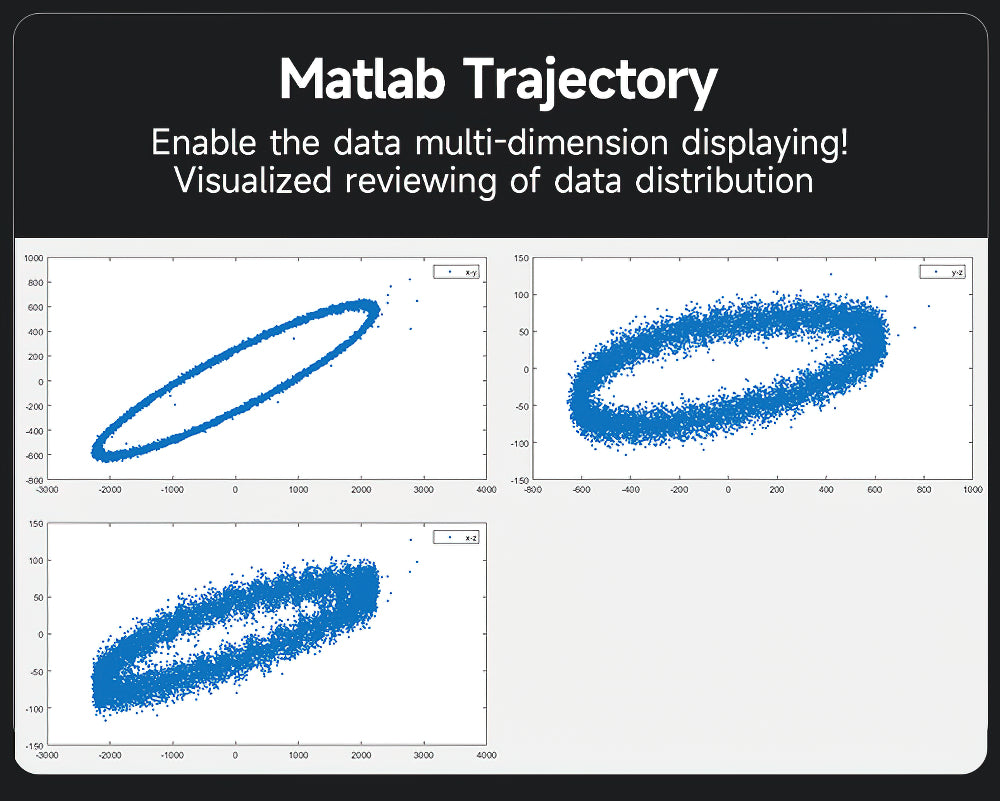

This along with the app lets you monitor and log vibration. I use it to detect imbalance in high-speed motor applications. Great for collecting data.

![[WT901SDCL-BT50] Bluetooth remote reading SD card Low-Power Accelerometer, 9-axis Gyro+Angle+Mag - WitMotion ShenZhen CO.,LTD](http://witmotion-sensor.com/cdn/shop/files/5.0.jpg?v=1742436210&width=1946)