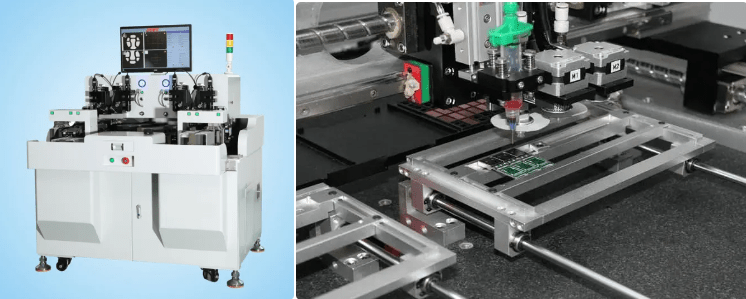

The high-precision die bonder, also known as a crystal chip bonding machine, is a mechanical device used for fixing crystals and semiconductor packaging. It is mainly applied in various wire bonding (WIRE BONDER) ultrasonic gold wire welding systems — specifically in the lead frame clamps and pressure plates — as well as in die bonding (DIE BONDER) systems, which include components such as suction nozzles, ejector pins, dispensing heads, ceramic nozzles, through-pins, motors, carbon brushes, encoders, drive belts, and a variety of spare parts for automation equipment, instruments, and meters.

By integrating the HWT9073-485 accelerometer sensor into the PCBA board through circuit design and firmware programming, both high precision and high-speed control can be achieved.

This enables a single machine to be compatible with all types of LED die bonding operations. Features include:

-

Quick product changeover

-

Dual-vision positioning system for high bonding accuracy

-

Modular auto-teaching for simple and fast setup

-

Supports both single-point and two-point positioning to accommodate diverse production needs

-

Automatic tray loading/unloading of frames; only the fixture needs to be changed for different products

In operation, the PCB is first transferred by the feeding mechanism to the working position on the fixture. The dispensing mechanism applies adhesive to designated bonding points on the PCB. The bonding arm then moves from its home position to the chip pick-up location, where the die is placed on a film-supported expander tray. The nozzle moves downward to pick up the die, lifts it, and returns to the home (die inspection) position. It then moves to the bonding location, places the die, and returns again—completing one bonding cycle.

After each cycle, the machine vision system identifies the next die location and sends the data to the motor of the die tray. The motor then moves the tray so the next die is aligned with the pick-up position. The PCB's adhesive bonding process follows the same routine until all bonding points are completed. Finally, the conveyor system removes the finished PCB and loads a new one to begin the next work cycle.

Learn more about the HWT9073-485 inclinometer specifications:

https://witmotion-sensor.com/products/ahrs-built-accelerometer-in-mmc3630-mag-filed-chip-and-ip67-waterproof